HRE is back with the second generation of their 3D printed titanium wheels. The custom wheel manufacturer has partnered with General Electric’s additive manufacturing wing to revolutionize wheel design and manufacturing.

Half a year ago, they unveiled their first prototype – HRE3D+ – a wheel so intricate and delicate, it looked more like a fine sculpture than a working vehicle component. Yet, it was made out of solid titanium – incredibly strong, light and corrosion resistant.

The second version is even more refined. HRE has improved the design to make better use of the 3D printing technology, producing a lighter and more efficient wheel with fewer parts and less waste.

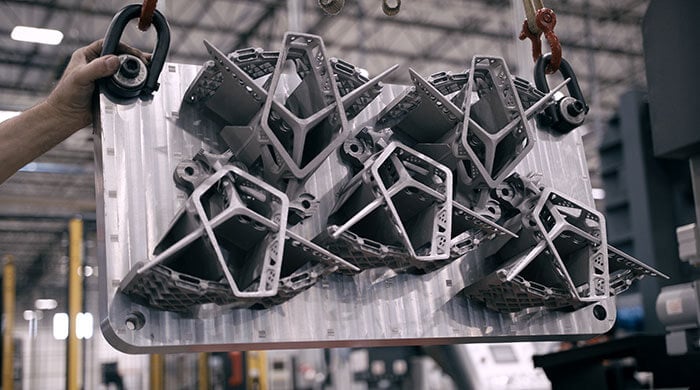

Five interlocking sections join at the wheel studs to make the central hub and spokes. The assembly is bolted with titanium fasteners to a carbon fiber barrel to make the final wheel.

The 20” x 9” wheel weighs just 16 lbs and the 21” x 12.6” – 19lbs. At the same time, just 5% of the raw material is discarded as waste vs 80% in typical billet machined wheels.

HRE and GE Additive presented their work at the RAPID + TCT 2019 – North America’s largest additive manufacturing trade show. The wheels were installed at the front and back of Graham Rahal’s stunning 2019 Ford GT.

Frankly, this car with these wheels is one of the most beautiful things we’ve seen in the automotive world this year.

So, how did they make them? HRE made use of two 3D printed technologies offered by GE Additive.

One of them is Electron Beam Melting – EBM. Loaded with a CAD file, the machine layers fine titanium powder and shines a 3,000 – 6,000 Watt electron beam to melt it and produce one solid cross-section. The process repeats layer by layer until the final part is printed in full.

During the operation, the chamber is kept hot at 1,800 F to allow the titanium layers to fuse into a solid piece of metal with no defects and residual stress. The vacuum ensures the chamber is kept clean.

The second technology Direct Metal Laser Melting – DMLM is similar. A laser is used to melt layers of titanium powder one after the other to create the final part.

Both technologies are incredibly precise and produce solid metal objects with exceptional dimensional accuracy and material qualities. The post-process work is very little – mainly removing any support structures and machining mating surfaces. Since titanium is corrosion resistant, no coating or painting is needed.

While metal 3D printing is still a very expensive technology, we’re starting to see a transition from purely research and development projects to actually functional projects which see real-world applications.

- Bugatti’s 3D printed titanium brake calipers, which showed extreme levels of performance and will eventually make it into the Chiron.

- Ford Performance created a bespoke 3D printed intake manifold for Ken Block’s ridiculous Ford F150 Hoonitruck.

These developments are most exciting as they are paving the way for the next evolutionary step in automotive engineering.