The McLaren 720S Spider launched this month in Arizona. We showed you the first video of the car by blogger Mr. JWW and it is phenomenal. The Spider retains the performance of the 720S Coupe and adds exciting new features, like the “electrochromic” sunroof.

An interesting fact is the vehicle comes with an open differential on the driven rear wheels.

In an interview with Car Throttle, Ian Howshall – Global Product Manager for the Super Series line at McLaren, commented on this decision. Mr. Howshall shared the open differential was chosen as a means to save weight and improve efficiency.

“If we have a limited-slip differential or an e-diff, we add weight…What the brakes do is grab the inside wheel to help the car rotate. Because you’re using components already there, you’re not adding any extra weight”.

This is not limited to the 720S model. All McLaren vehicles are using an open differential.

Okay, to make more sense of this, we need to back up a bit and talk about vehicle dynamics; how differentials operate; and what is torque vectoring.

What does the differential do?

On the straight, all wheels will rotate at the same speed. Simple enough.

But when the car goes into corner things get interesting. A corner is effectively part of a circle that has a center point somewhere in space.

As the car turns, all wheels travel around the same center point, but trace different sized circles. The outer wheels trace bigger circles and need to travel a longer distance. Therefore they need to rotate faster in order to keep up.

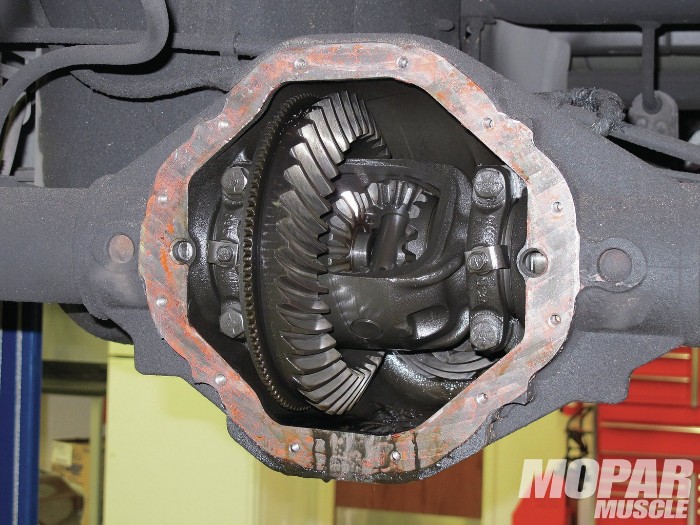

That’s possible thanks to the differential – a rather fascinating mechanism. It takes a single torque input from the driveshaft and transfers a varying amount to either axle. The amount depends on the resistance each wheel “feels” from the road.

An open differential is the simplest version. It allows the wheels to move at different speeds and doesn’t offer any control over how the power is split. The majority of cars use an open differential. Even all-wheel-drive vehicles and SUVs usually use open differentials.

What’s weird about an open differential in a sports car?

With an open differential, power follows the path of least resistance. The mechanism will always transfer torque to the wheel that’s less loaded.

If one wheel is on ice and the other on pavement, the first wheel will spin out because it has less traction. Often, the wheel that has traction will not receive enough power to move the car off the icy patch and you’ll get stuck.

During cornering, centrifugal forces will push the car from the inside out, shifting its weight on the outer wheels. Since the inner wheels are less loaded, the open diff will send more power to them.

That’s fine if you do normal driving in a regular car. But it’s exactly the opposite you want to happen when you’re taking your McLaren for a hot lap on the track.

Because of the weight shift, the inside wheels have less traction and are prone to spinning if you put a lot of power down. At the same time, the outside wheels which do have grip and need to travel further receive just a small portion.

This can really limit your performance in the corner and slow you down considerably.

Limited-slip differentials

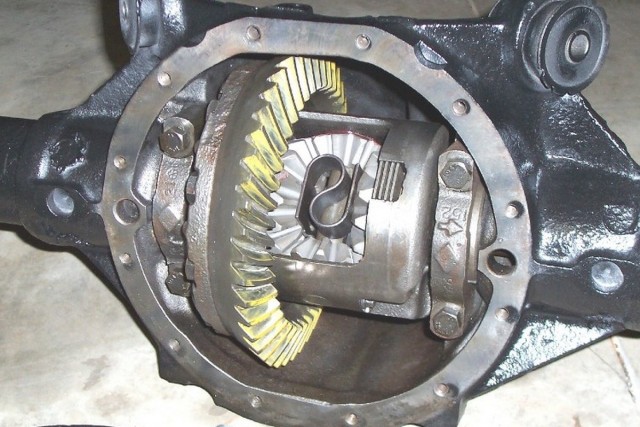

Limited slip differentials solve the traction problem. True to their name, LSDs prevent one tire from slipping too much by locking both half-axles together and transferring the same torque to both wheels.

There are many different types of limited-slip or locking differentials. They achieve the same result by different means:

- Clutch type – The half-axles are connected to the differential using clutch packs. A strong spring in the center pushes the clutch packs engaged, preventing either wheel to spin excessively. In normal driving conditions, it works as an open differential.

- Electronically controlled clutch type – The clutch packs are controlled by the vehicle’s computer. When a speed sensor detects that either wheel is spinning, the computer will engage the clutch pack of the other half-axle, locking the system together.

- Gear type (Torsen) – Uses a worm gear and wheel mechanism. It locks both axles together if one starts spinning much faster than the other. Any traction difference will cause the unit to lock up instantaneously.

- Viscous coupling unit – As the wheel without traction goes into a spin, the pressure in the viscous coupling unit forces the opposite wheel to turn as well.

- Locking differential – The driver can engage the lock and force both wheels to rotate at the same speed at all times.

Limited-slip differentials ensure the wheels that have traction always receive power. This is essential in performance driving. Most sports cars, muscles and supercars feature some limited-slip or locking differential technology.

However, LSDs are heavier and more complex than the simple open diff. They also create more frictional losses in the drivetrain and demand more power and fuel.

It makes sense for a manufacturer obsessed with power to weight ratios to look for alternative options.

McLaren invented torque vectoring in Formula One

In the late 1990s, McLaren’s F1 team realized that in order to make faster turns, they needed to modulate how much power the inner and outer wheels get.

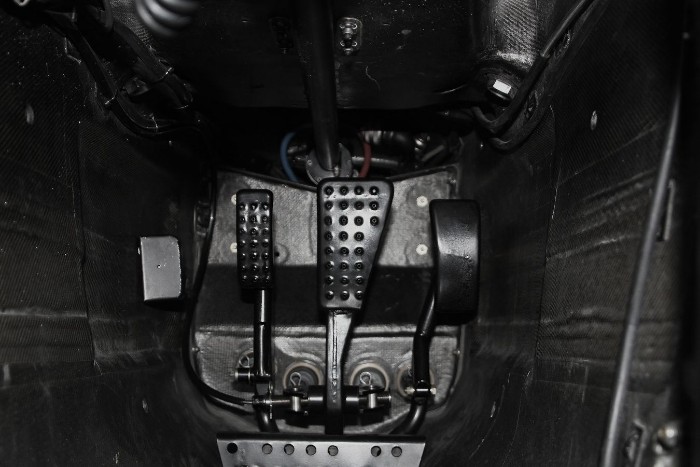

In 1997, the MP4/12, driven by Mika Hakkinen, featured a unique brake. It came with its own pedal and would operate either the left or right rear wheel brakes. The setup was chosen for each specific track, depending on how many left or right turns it featured.

When Hakkinen would go into a corner, he’d apply the special brake, slowing down the inside wheel and allowing the car to rotate more easily at high speed. This was the first instance of torque vectoring used in automotive technology.

The technology proved effective but after disputes and complaints from the competition, it was ultimately banned the following year.

Although it never took off in F1, the technology is present in all modern vehicles. Almost every new car, regardless of its class, comes with safety features like stability control and traction control. The computer takes input from the speed sensors on each wheel and activates the brakes accordingly.

In the case of McLaren, the computer tells the brakes to grab the inside wheels, helping the car rotate and transferring the power to the wheels that have grip.

The pros and cons

McLaren decided their cars don’t need limited-slip differentials and can instead rely on brake-based torque vectoring. This allows the engineers to shed some precious pounds off the curb weight and remove some of the complexity associated with LSD.

McLaren supercars already have very powerful brakes that are operated by the computer. So they are not adding any additional hardware.

Ian Howshall further commented: “It’s more effective with our cars … the tire performance, the power, the brakes, the weight of the car – it really helps it rotate and you can feel it when it happens”.

On the downside, using the brakes means taking away power from the engine. There is an argument to be made whether the weight savings justify the loss of efficiency.

Furthermore, brake-based torque vectoring introduces additional wear to the brakes. On a very curvy road or track, the rotors can heat up excessively, which reduces their effectiveness. McLaren needs to make sure their brakes are spec’d accordingly to the task.

Finally, limited-slip differentials are more predictable and offer the driver more control. A mechanical link will operate the same in similar conditions. As you drive the car, you can get accustomed to the way a limited-slip differential operates.

With McLaren’s approach, the computer will calculate each situation and always apply a unique solution according to the math. It’s still a smooth process, but it’s not an instantaneous mechanical lock like with a Torsen differential.