Ever since they announced the new Supra will use a BMW engine, there has been serious doubt if the car will live up to its name.

The A80 Supra only became a legendary vehicle because of its 2JZ engine. The success of the 2020 Supra will depend almost entirely on whether or not BMW’s B58 engine is as good as Toyota’s old 2JZ.

Thanks to Stephen Papadakis from Papadakis Racing, we can finally see what’s inside the rumored engine and get the first hints onto whether or not it will hold some power.

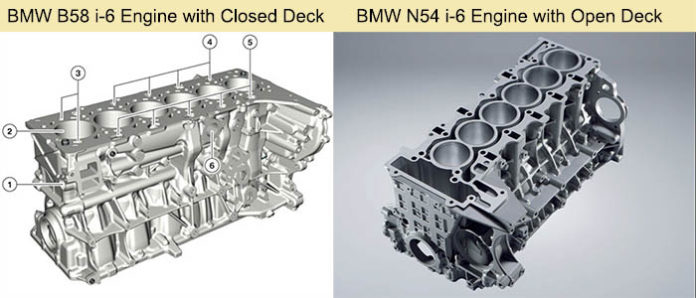

Closed deck design

A closed deck design has the top face of the engine block completely solid, except for a few passages for coolant flow. This makes the block a lot more rigid and provides support for the top of the cylinders, where combustion occurs and produces the highest pressures in the engine.

If you want to make big power, you need to start with a closed deck block. The 2JZ engine also had one.

It’s important to note that 2JZ had a cast-iron block and the B58 has a solid aluminum one. Cast iron is typically stronger, but also heavier.

Modern aluminum alloys have come a long way and the B58 engine has several reinforcement features which give it extra rigidity.

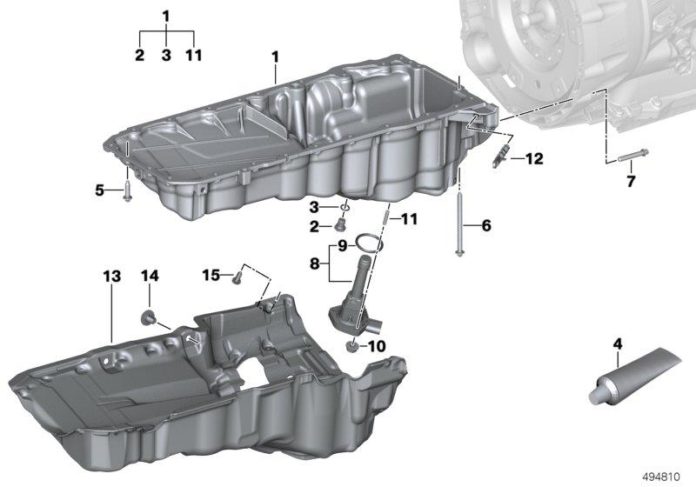

The oil pan is a big chunk of solid aluminum, bolting over the entire bottom surface of the block.

Between the pan and the crankshaft, there is an aluminum girdle, which bolts to all 6 main bearing caps and the sides of the block at the same time. The girdle also doubles as a windage plate, keeping the crankshaft free of excess oil, therefore improving efficiency.

This double reinforcement holds the entire block together and prevents flexing as power is increased.

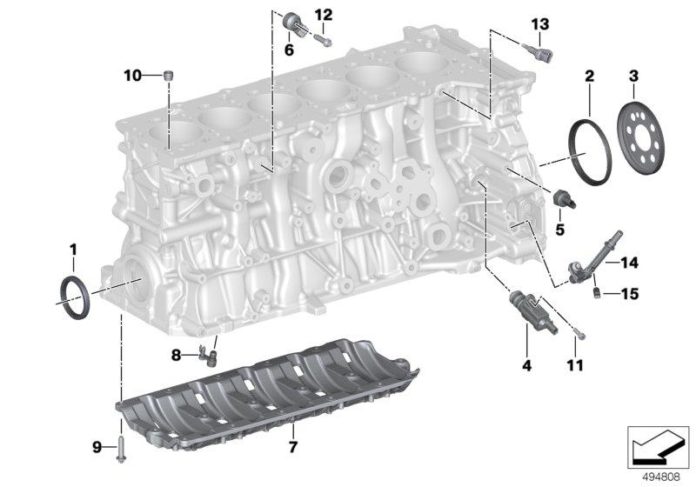

Forged rotating assembly

The B58 engine has forged crankshaft, connecting rods, and pistons.

Of course, any performance engine would require forged internal components rather than cast ones. Casting is cheaper, but can leave imperfections within the material like internal pores, which become failure points when subjected to extreme loads.

Forging uses a pre-cast material which is carefully controlled for quality and the process increases the density of the material, making it tougher and more durable.

Both the 2JZ and B58 come stock with a forged rotating assembly which is key for making power reliably.

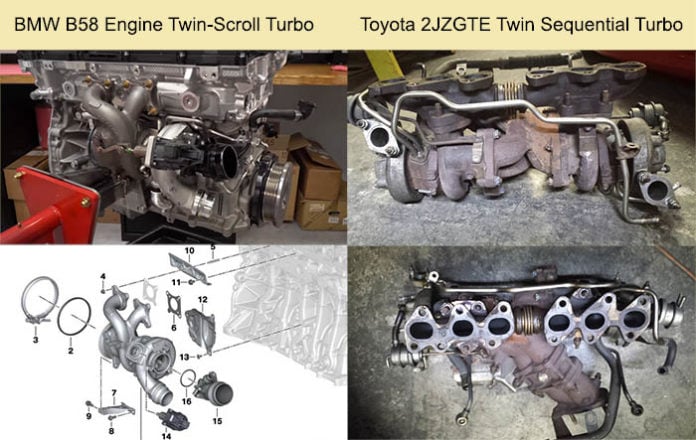

Different turbo strategy

The two engines use a different turbocharging strategy.

The 2JZ uses a sequential turbocharger setup, where one turbo will activate at low RPM and the second one will start at 3,500 – 4,000 RPM.

The B58 uses a single twin-scroll turbocharger, separating the exhaust flow from the cylinders, preventing them from interfering with each other.

The exhaust manifold is integrated into the cylinder head, so modifications would require an entirely new head altogether. However, this design adds strength, improves the packaging and shortens the path the exhaust gasses need to travel.

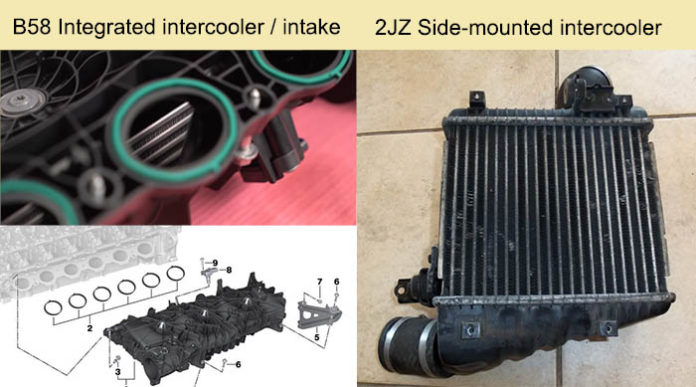

B58 uses a water-to-air intercooler versus an air-to-air intercooler on the 2JZ. It’s integrated into the intake manifold and cannot be extracted easily. A separate pump circulates the liquid to a front-mounted heat exchanger.

It’s a more complicated system and, similar to the exhaust side, it will be very difficult to modify if needed. However, it improves the packaging, weight and travel distance of the charged air.

As a result of these strategies, the turbo on the B58 spools up very quickly and produces maximum torque at only 1,500 RPM, whereas the 2JZ reaches max torque at 4,000 RPM.

In conclusion

There are many more components like variable valve timing and lift, ignition system and tuning of the ECU itself.

They can hardly be compared between the two engines, so we’ll leave the tuners to figure it out and we’ll compare the results, when they are in.

However, mechanically speaking, it looks like the BMW powerplant has what it takes to make big power.

Stephen Papadakis will be shooting for 1,000 hp with this B58, so we’ll know how well it holds soon enough.

Below, you can see him breaking down an old 2JZ engine in a similar fashion and you can see more of the similarities and differences for yourself.