Ken Block’s Gymkhana Ten movie is a smashing success and clearly a tire slashing festival.

We really need to hand it to Ken Block. He’s a true master of throwing the vehicle around and clearing obstacles with just inches of clearance. The level of control and precision required for some of the stunts is just mind-boggling.

But none of Ken Block’s performances would be possible if it wasn’t for the five amazing machines and the talented engineers that built them.

Arguably, the most impressive vehicle was the 1977 Ford F-150 drifting pickup, dubbed the Hoonitruck.

It was developed by Detroit Speed and Ford Performance. A number of companies have contributed custom components to make this the ultimate performance truck.

Exterior design and body

The Hoonitruck is a 1977 Ford F-150 pickup truck. Surprisingly, the truck retains quite a few elements from the original body.

The grille, headlights, side mirrors, and emblem are stock with ceramic coating to match the Hoonigan style. New carbon fiber bumpers and splitter are added.

It’s hard to miss the element of massive wheel arches. The Hoonitruck is more than 80 inches wide. The wheels actually sit on the outside of the body panels. The truck doesn’t fit inside of a trailer without partial disassembly.

All the body panels are hand built. They follow the original design closely with a large groove running down both sides of the vehicle. Aluminum was chosen to connect the project with the current technology used in the F-150.

At the back there is a large wing mounted on the tailgate. It’s not there to create downforce, but really as a safety device to protect the truck.

Trucks are not really meant for drifting, less so in tight spaces. So, when Ken Block inevitably scrapes something when spinning this Godzilla around, the wing will take the hit, rather than the back end.

Chassis and suspension

The chassis of the Hoonitruck is really incredible.

Considering its working conditions, no matter how well built, this truck is prone to sudden and catastrophic damage. So, what do you do when Ken Block misses the gap and tears a section of the bed off the truck?

Well, the engineers at Detroit Speed designed for that and made the chassis modular. It’s made up of 4 sections, assembled with clevis joints.

- The tail section

- The rear suspension subframe

- The monocoque cabin

- The front suspension subframe

Each of these can be detached and replaced with a spare as quickly as 30-45 minutes.

Furthermore, the chassis has breakpoints designed to fail when the truck receives damage. This way, the chassis breaks cleanly, protecting the internal components from further damage.

This allows the crew to make quick repairs and get the truck back on the road, so it can continue filming.

The mounting points for all suspension components are fully adjustable. The front and rear suspension uses the same components. Minus some minor modifications, the uprights, lower and upper control arms are the same ones that Detroit Speed sells off the shelf.

Wheels and tires

The truck rides on a set of custom 20×11-inch forged Turbomac HD wheels. The wheels are co-developed by Fifteen52 and Ken Block. Normally, they don’t come in this size, so the set was custom built for the Hoonitruck.

The wheels are wrapped in Toyo Tires – Proxes ST III. They measure 315/35 R20 and are actual production SUV tires which are available for sale by Toyo.

Stopping power comes from a set of six-piston Wilwood brakes with 14-inch rotors all around.

Powertrain and performance

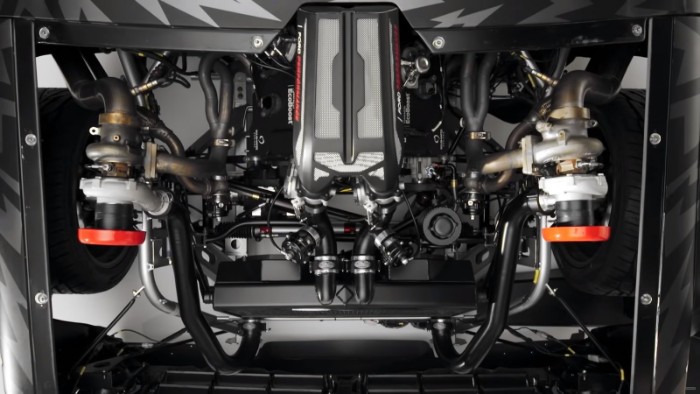

We saved the best for last. The Hoonitruck is powered by a custom 3.5-liter, twin turbo, EcoBoost V6 engine. This engine is used in a number of Ford vehicles, including the F-150 and GT.

It’s developed by Ford Performance and Roush Yates and features groundbreaking technology. Total power output is 914 hp and 702 lb/ft of torque.

The block is billet machined and comes from the Ford Racing GT program. The same program developed the Ford GT, which won the LeMans in 2016.

The Garett twin turbochargers are designed specifically for this application. They breathe through a large intercooler with a dual fan system. The fans make sure there is enough airflow even when Ken is just burning tires in a standstill.

The air makes its way into a custom-designed, 3D printed intake manifold. The manifold is a product of phenomenal engineering and cutting edge manufacturing technology by Ford Performance.

The radiator and oil cooler have been moved into the bed, behind the cabin, to free up space in the engine bay.

The transmission is a Sadev, 6-speed sequential 4WD transaxle. It delivers power to both differentials, instantaneously lighting all four wheels on fire. Rated for 719 lb/ft of engine torque, this transmission is designed for drifting and rally applications.

Overall, the Hoonitruck is a phenomenal feat of automotive engineering. It’s a moving piece of art that truly shines in the hands of its master. We leave you with an extended cut of Ken Block ripping it up in the Hoonitruck.